how to weld aluminum

A Guide to Welding Aluminum. J-B WELD ORIGINAL.

How To Weld Aluminum For Beginners Youtube

Take the time to prepare your aluminum.

. Ad Manufacture Steel Tubing Track PBR Cut-to-size Sheet Slotted Angles. Aluminum melts at about 1200 degrees fahrenheit. Check Out Our Steel Stainless Steel Aluminum Hardware Ornamental Fence Supply.

Like auto pistons aircraft marine valves bikes structural aluminum beams. Large weld depth resulting in narrow heat-affected zones. Check Out Our Steel Stainless Steel Aluminum Hardware Ornamental Fence Supply.

The more the operator can narrow-down the melting range of the metal the easier it. Written by David Harper in Welding Guide. Use DC reverse polarity.

Pick the right tungsten electrode or rod the best choice for aluminum is typically a pure tungsten rod. When welding aluminum pipe it is a good idea to begin with clean metal ends where you intend to weld the pipe together. How to avoid porosity in Aluminum welding.

Avoid pulling while weldinginstead push at a 10 degree to 15. J-B Weld Original provides strong lasting repairs. Increase the travel speed and make shorter welds.

Most likely the best JB Weld product for aluminum would be their Marine Weld option. Select an aluminum filler wire that has a melting temperature similar to the base material. Ad Manufacture Steel Tubing Track PBR Cut-to-size Sheet Slotted Angles.

How to Weld Aluminum. It is designed for boats that must handle very tough conditions that most RV users do not face. Aluminum will start to melt at 1200deg Fahrenheit but the brazing rod will melt at around 700deg so we want to get.

Welding aluminum is considerably more straightforward than you may imagine. Prepare your push-pull wire feed. Move around on the part spreading out the heat.

Welding is the process of bonding metal together with. Laser beam welding can be used with. If youre a beginning welder theres a strong chance youll weld aluminum in your future ca.

Aluminum welding is used on planes boats motorcycles and more. Use thicker material change the joint design or switch the welding. Firstly you need to get your flux-coated aluminum electrode ready prepare the base metal set the current and polarity on the welding machine right and start welding.

Preparation The first step to gas weld aluminum is cracking the oxide layer. The Original Cold Weld two-part epoxy system that was designed as an alternative to torch welding. The oxide layer has a melting temp of 3722F 2050C and the aluminum on its own.

Over time aluminum forms a thin coat of aluminum oxide on its exterior which melts at a much. Welding aluminum makes countless products possible. Setting up the Work Space Download Article 1.

Keyhole laser welding is capable of producing high aspect ratio welds narrow weld width. Clamp up the tubing and start heating the aluminum with a propane torch. Aluminum and its alloys are highly susceptible to weld metal porosity bubbles of hydrogen due to the high solubility of hydrogen in it.

Clean your aluminum remove any oxide and file the edges that will be joined.

How To Weld Aluminum Pipe Youtube

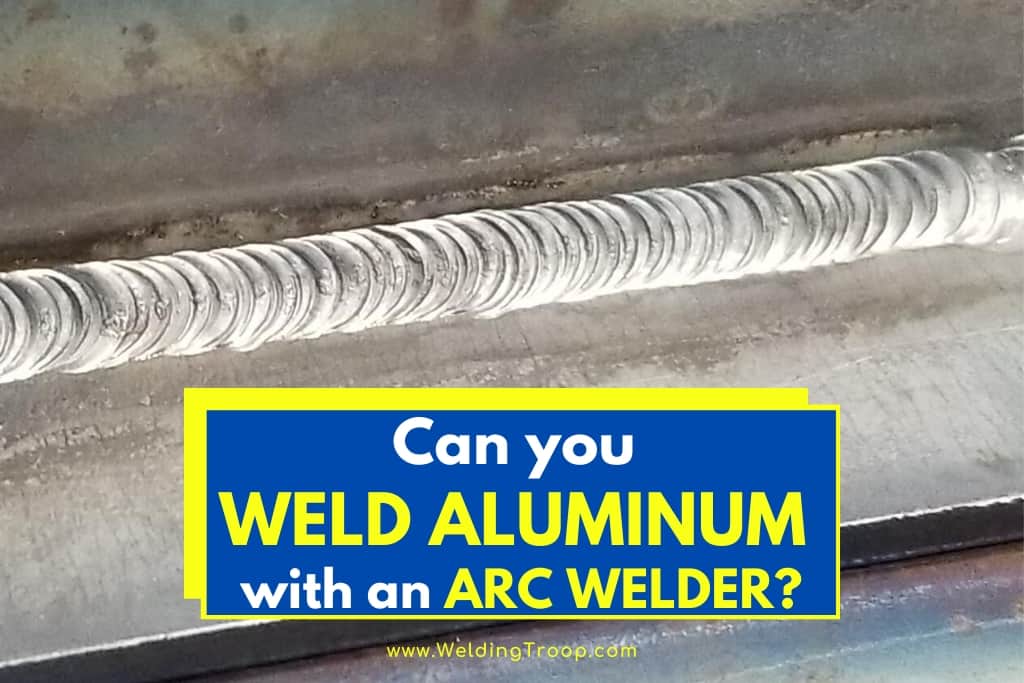

Can You Weld Aluminum With An Arc Welder All You Need To Know

How To Weld Aluminum Without A Welder

How To Weld Aluminum Australian General Engineering Vietnam Metal Fabrication Vietnam

How To Weld Aluminum With Pictures Wikihow

How To Weld Aluminum With Pictures Wikihow

0 Response to "how to weld aluminum"

Post a Comment